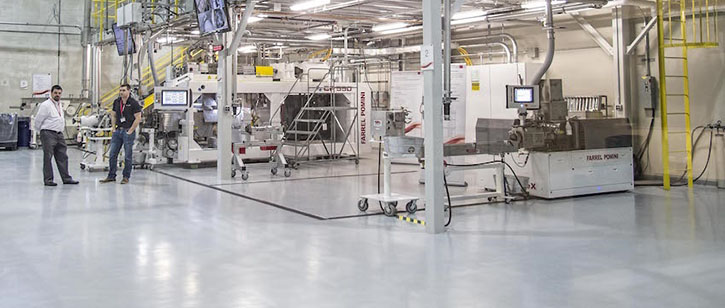

Industrial Polished Concrete Floors

Abusive environments and tight schedules are the norm for industrial floors, and they are business as usual for us. As a leading industrial flooring contractor we work during off-hours and have heavy duty industrial flooring options that provide a quick return to service.

We are qualified and experienced to work around most chemicals and our industrial flooring technicians are respirator trained in addition to being part of a medical monitoring program.

We are experienced with all the problems an industrial environment poses. We use state-of-the-art products that will enable you to returned to service in a matter of hours. We use products that can be applied to oil soaked floors or wet floors. Our grinding equipment is HEPA filtered and low noise, and we routinely work in active facilities with employees working directly next to the area we are coating.

Industrial Floor Striping

Keep your facility neat and orderly, prevents accidents, improve morale, and impress customers, regulators and recruits. We offer a variety of industrial line striping services for warehouses, however, we do not stripe parking lots.

Our industrial line striping services include:

- Vinyl Tape line striping Heavy Duty

- Epoxy Line striping

- OSHA Markings

- Kaizen markings

- 5S

- Six Sigma

- TQM

Industrial Wood Block Flooring

Industrial wood block flooring is still in used in many facilities today because it is a cost-effective and durable option. We provide repair, restoration, or removal services for industrial wood block flooring systems. We have an amazing sealer that will bond to oil soaked industrial wood block floors and restore them. This provides a great alternative to the expensive project of removing and replacing an industrial wood block floor.

We can perform spot replacement of damaged wood blocks or complete removal and replacement. Replacement can be with new wood blocks, new polymer blocks, self-leveling concrete, or epoxy floor systems.